Table of contents

In the ever-evolving world of fashion, technology is making its mark with an innovative trend: 3D printed clothes. This revolution in clothing production merges design and manufacturing into a seamless process, breaking traditional barriers while offering limitless possibilities for customization and sustainability. Imagine wearing garments that are tailor-made to fit your body perfectly or showcasing unique designs impossible to create using conventional methods - welcome to the future of fashion! The following paragraphs delve deeper into this fascinating subject, uncovering how this new technology works, its benefits and challenges, and what it means for the global fashion industry.

Understanding How 3D Printing Works in Fashion

3D printing, or additive manufacturing, is rapidly transforming the fashion industry. It offers a novel fabrication process that allows designers to create bespoke pieces with intricate designs and perfect fit. Its application in crafting garments involves the use of digital modeling techniques to create a design blueprint. The chosen design is then transferred to the 3D printer, which builds the garment layer by layer, hence the term 'additive'.

The materials used in the production of 3D printed clothes vary vastly. They range from plastics, such as polylactic acid (PLA) and acrylonitrile butadiene styrene (ABS), to more flexible materials like thermoplastic polyurethane (TPU). These materials are meticulously selected to ensure durability, flexibility, and above all, comfort to the wearer. Furthermore, with sustainability being an imperative aspect of modern fashion, recycled materials are also employed in the production process.

3D printed clothing's uniqueness lies in its customization. Unlike traditional manufacturing, additive manufacturing allows for garments to be tailor-made according to individual needs and preferences. This level of customization was previously unthinkable and is revolutionizing the fashion industry.

The Potential Benefits Offered by 3D Printing Clothes

One of the prominent advantages of 3D printed clothes is the cost-effectiveness. This innovative method of production allows for a less wasteful approach than traditional clothing manufacturing processes. The minimized waste not only reduces production costs but also contributes to the reduction of the environmental footprint.

Alongside cost-effectiveness, 3D printing introduces a new level of creative freedom in the fashion industry. The technology allows for unlimited design potentials, creating opportunities for designers to experiment and innovate without the constraints of traditional tailoring techniques.

Next, the advent of 3D printing brings about the benefit of size inclusivity. With the ability to take precise measurements digitally, this technology ensures that clothes fit perfectly regardless of the wearer's size. This emphasis on customization also enhances the overall comfort and fit of the garment, revolutionizing the way we perceive clothing sizes.

Lastly, the process of 3D printing clothes is inherently more environmentally friendly. The method significantly reduces wastewater usage and eliminates the need for harmful chemical dyes, making it a more sustainable choice in clothing production.

In essence, the revolution of 3D printed clothes brings about a multitude of benefits including cost-effective production, enhanced creative freedom, size inclusivity through precise measurements, and the ability to reduce the environmental footprint. These advantages not only revolutionize the fashion industry but also contribute to a more sustainable world.

Acknowledging Challenges Involved with 3D Printed Clothing

While the allure of 3D printed clothing offers tantalizing possibilities, it's imperative to understand that a number of obstacles still need to be surmounted. One of the primary concerns associated with this innovative technique pertains to 'quality control.' Ensuring consistency and durability of the finished products is paramount, yet poses significant difficulties at this stage of the technology's development. In parallel, 'scalability' presents its own set of challenges. The 'technical complexity' associated with expanding production on a large scale is substantial, and not to be underestimated.

Furthermore, another factor to consider is the 'initial investment'. The setup of 3D printing machinery, known for its high costs, can potentially deter many interested parties. Lastly, 'personnel training' is an integral aspect that needs significant attention, as operating 3D printing machinery and software efficiently requires specialized skills. While these challenges may seem daunting, addressing them head-on is necessary for the successful expansion and development of 3D printed clothing.

On the same subject

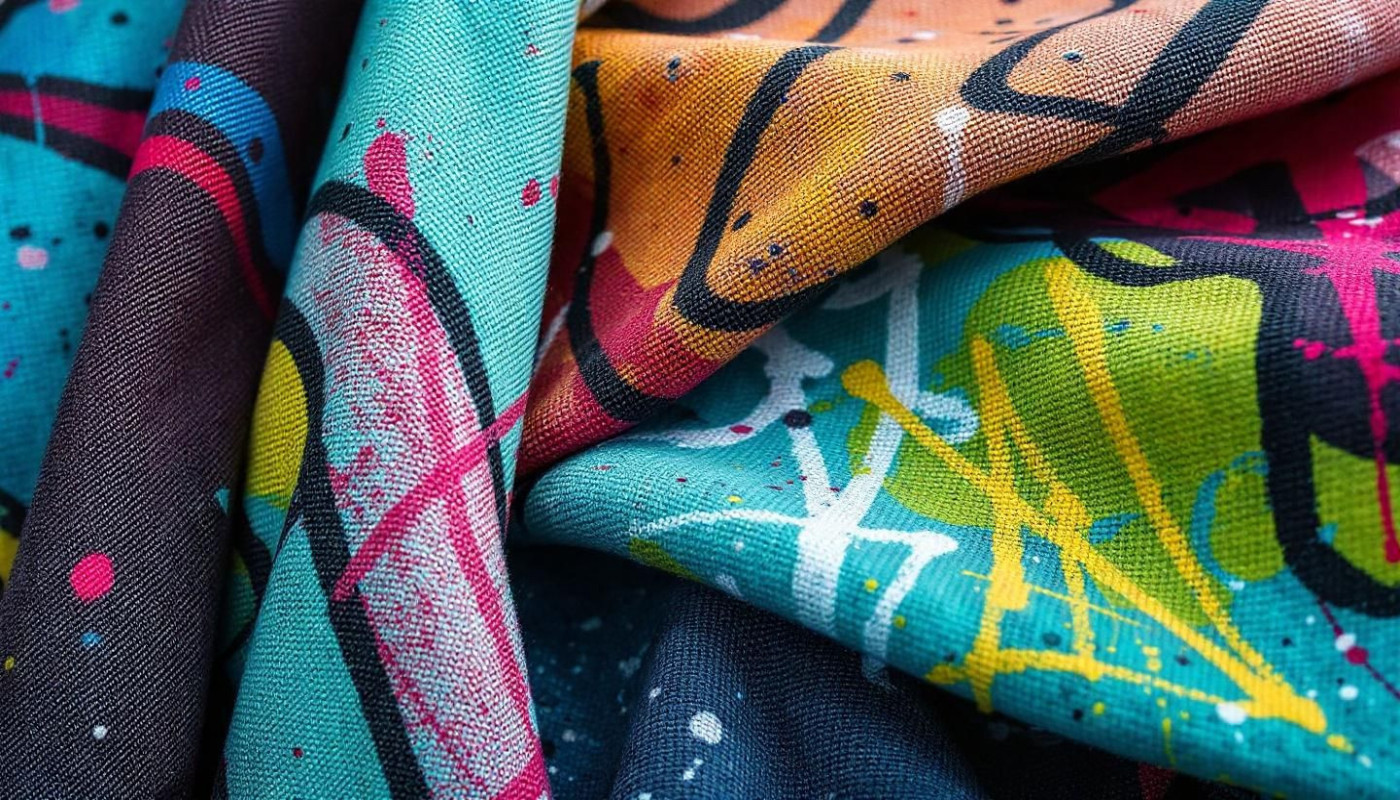

The Significance Of Fabric Choices In Defining Streetwear Aesthetics

Exploring The Timeless Appeal Of Bohemian Dresses In Modern Fashion

Exploring The Impact Of Hip-hop Culture On The Popularity And Design Of Urban-style Jeans

The Retro Revival: Exploring The Comeback Of Parachute Pants In 2023 Fashion Trends

The Evolution Of Rasta Fashion: From Rebellion To Mainstream

Mixing And Matching: How To Style Cow Print Slippers With Your Everyday Wardrobe